Best Prefabricated Modular Buildings You Should Know About?

Prefabricated modular buildings are changing the construction landscape. These innovative structures offer speed, efficiency, and versatility. They can serve various functions, from homes to offices, all built with remarkable precision.

Imagine a building that comes together like a puzzle. Each module is crafted off-site, ensuring quality control. Once ready, they are assembled on location, reducing construction time significantly. However, while these buildings present numerous advantages, challenges do exist. Some critics argue about their aesthetic appeal and long-term sustainability.

Design options are diverse, yet customization can be limited. Not every prefabricated modular building fits every need. It's essential to weigh these factors carefully. In a world increasingly focused on sustainability and efficiency, understanding these nuances is vital. The rise of prefabricated modular buildings invites us to rethink traditional construction methods and their implications on our environment.

Overview of Prefabricated Modular Building Industry Growth and Trends

The prefabricated modular building industry is experiencing notable growth. According to a recent report by the Modular Building Institute, the market is projected to reach $157 billion by 2026. This rapid expansion is driven by several factors, including a rising demand for cost-effective and sustainable building solutions. Many companies are turning to modular construction to minimize waste and reduce construction time.

Tips for choosing modular buildings: Consider the design flexibility. Modular buildings can be customized to fit specific needs, enhancing functionality. Additionally, evaluate the project timeline. Modular constructions often cut lead times significantly. Interestingly, while modular units can be efficient, some projects face delays due to logistics and site preparation. It's crucial to plan carefully.

The trend towards sustainable construction fuels this industry's growth. Many modular units use eco-friendly materials, aligning with global sustainability targets. However, challenges remain. Site conditions can impact the installation process. Moreover, not all modular solutions are streamlined; some require extensive coordination. Attention to detail during planning can mitigate these issues. The future is bright for modular buildings, but understanding potential hurdles is essential.

Best Prefabricated Modular Buildings You Should Know About

| Category | Common Applications | Size Range (sq ft) | Estimated Cost ($/sq ft) | Sustainability Features |

|---|---|---|---|---|

| Office | Workspaces, Meeting Rooms | 200 - 2,000 | $100 - $200 | Energy-efficient designs, Recycled materials |

| Healthcare | Clinics, Laboratories | 300 - 5,000 | $150 - $300 | Low VOC materials, Natural light integration |

| Residential | Single-family homes, Apartments | 500 - 3,000 | $80 - $250 | Solar panels, Smart home technology |

| Educational | Classrooms, Administration buildings | 800 - 4,000 | $120 - $220 | Green roofs, Water-saving fixtures |

| Industrial | Warehouses, Manufacturing spaces | 1,000 - 10,000 | $60 - $150 | Efficient insulation, Waste management systems |

Key Advantages of Prefabricated Modular Buildings Compared to Traditional Structures

Prefabricated modular buildings are gaining popularity. One key advantage is speed. According to a McKinsey report, these structures can be built 30% to 50% faster than traditional buildings. This is largely due to off-site construction processes. Components are manufactured in a controlled environment. This reduces delays caused by weather or labor shortages.

Additionally, there's a notable cost efficiency. A study by the Modular Building Institute shows that modular construction can save up to 20% on project costs. Lower labor expenses and reduced waste contribute to these savings. However, some critics argue that initial costs for modular units can still be high. Balancing expenses with long-term savings is crucial.

Sustainability is another significant benefit. Modular buildings often use eco-friendly materials. Many designs allow for better energy efficiency. Yet, not all modular buildings meet these standards. The push for better environmental practices continues. Each project presents unique challenges. It’s essential to reflect on how these structures fit into broader sustainability goals.

Top Prefabricated Modular Building Manufacturers and Their Notable Projects

The prefabricated modular building industry is booming. According to a report by Technavio, the global modular construction market will reach $157 billion by 2026. This growth stems from a rising demand for faster and more efficient construction methods. Many manufacturers are leading this trend, delivering innovative designs and sustainable projects.

Notable projects include modular schools, hospitals, and housing complexes. These structures are typically built off-site and can be assembled quickly on location. This approach significantly reduces construction time, often by 30% or more. However, challenges remain. Some projects face delays due to site preparation or local regulations. Quality control can also be an issue, as modules must adhere to strict standards.

Several manufacturers are addressing these challenges with cutting-edge technology. Integration of Building Information Modeling (BIM) enhances design accuracy. In addition, the use of eco-friendly materials is becoming more common. While the modular sector is evolving, it’s essential to consider these growing pains. As the market expands, so does the need for adaptive solutions to improve efficiency.

Best Prefabricated Modular Buildings Overview

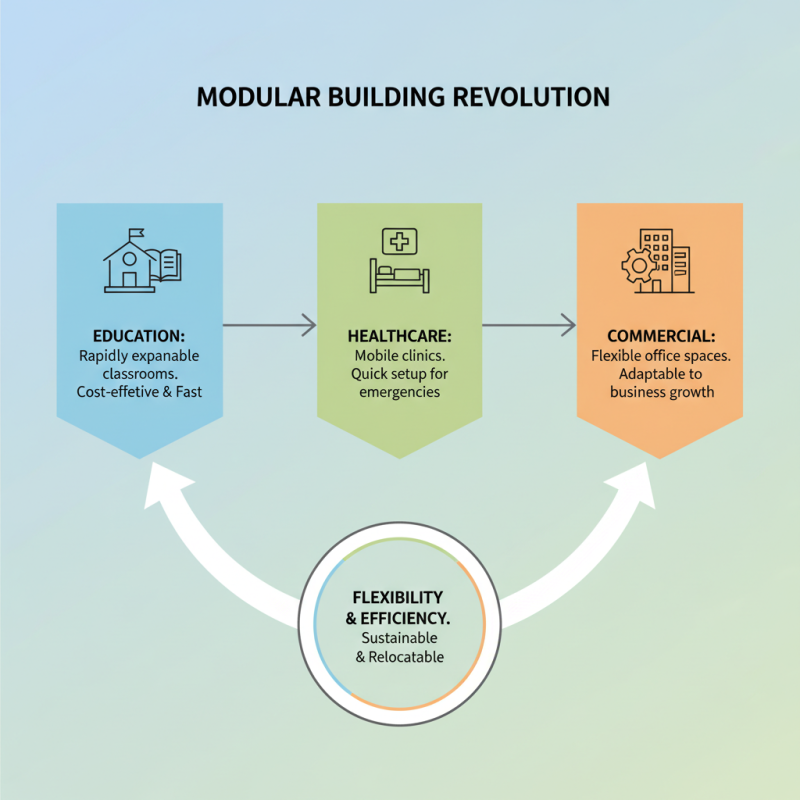

Innovative Applications of Modular Buildings in Various Sectors

Modular buildings are revolutionizing various sectors. These structures offer flexibility and efficiency. Schools are using modular classrooms to accommodate growing student populations. These rooms can be expanded or reduced quickly. They are cost-effective and can be installed in a fraction of the time compared to traditional buildings.

Healthcare is another area benefiting from modular designs. Temporary hospitals or clinics can be set up in just days. This rapid deployment can save lives during emergencies. However, these facilities sometimes lack the permanent feel. Patients may miss a sense of stability that traditional hospitals offer.

In the retail sector, modular buildings create pop-up shops and kiosks. These spaces allow brands to enter new markets swiftly. Customization is easy, yet it can be challenging to maintain consistency in branding. Each modular unit might look different, which can confuse customers. As modular buildings evolve, they continue to push boundaries while also prompting reflection on their limitations.

Cost Analysis: Understanding Budget Efficiency in Modular Construction

Modular construction offers a unique approach to building that can be both cost-effective and efficient. Many people are drawn to its quick turnaround times. However, understanding the cost implications is crucial. While initial costs can be lower than traditional methods, hidden expenses may arise. For example, site preparation and transportation fees can add significant amounts to the budget.

It's important to analyze not just the upfront costs. Lifespan and maintenance are key factors. A modular building may require fewer repairs over time, which can save money. However, if a building is poorly designed or constructed, costs can skyrocket in the long run. Engaging the right contractors and utilizing sustainable materials can enhance budget efficiency but might require careful planning and deliberation.

Every project is unique. Budgeting for modular construction also involves predicting future needs. Unexpected developments in the community may change the functionality of a building. This uncertainty makes it hard to forecast total expenses. Accurate budgeting requires reflection and adaptability throughout the process. Striking a balance between quality and cost efficiency is an ongoing challenge in the modular building arena.

Related Posts

-

Top 10 Benefits of Transportable Container Homes for Modern Living

-

Top 10 Tips for Choosing Prefabricated Modular Homes for Your Dream Home

-

What is Prefab Buildings and Why They Are Revolutionizing Construction

-

How to Build Steel Modular Homes in 2025 for Sustainable Living

-

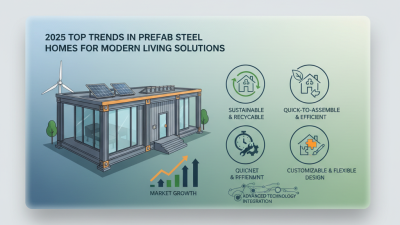

2025 Top Trends in Prefab Steel Homes for Modern Living Solutions

-

Top 10 Benefits of Transportable Container Homes for Modern Living?